How Sandblasting can Save You Time, Stress, and Money.

Wiki Article

6 Easy Facts About Mobile Sandblasting Near Me Described

Table of ContentsThe 2-Minute Rule for Sandblasting Near MeAn Unbiased View of Pressure Washer SandblasterThe smart Trick of Sand Blaster Harbor Freight That Nobody is DiscussingSand Blaster For Sale for BeginnersThe Ultimate Guide To Sand Blaster For SaleNot known Details About Dustless Blasting Near Me

Wet unpleasant blasting uses water as the fluid relocating the abrasives. The water supports the impact on the surface, minimizing the removal of audio material. One of the initial leaders of the damp rough procedure was Norman Ashworth who found the advantages of making use of a wet process as a strong option to completely dry blowing up.

Minimized impregnation of blowing up material right into the surface, dirt reduction as well as the elimination of static cling can result in a very tidy surface area - sandblaster for sale. Damp blowing up of mild steel will certainly result in prompt or 'flash' rust of the blasted steel substratum as a result of the presence of water. The absence of surface area recontamination also enables the usage of single devices for several blowing up operationse.

Some Known Facts About Sand Blaster Harbor Freight.

Vapor blowing up [edit] A variant of damp blowing up is vapor blasting (or vapour blasting; U.K.). In this process pressurized air is included in the water in the nozzle generating a broadband mist, called "vapor". This procedure is even milder than wet blasting, permitting mating surfaces to be cleaned while retaining their capability to mate.Mixing bits with water significantly lowers dust. Grain blasting is the process of getting rid of surface area deposits by using great glass grains at a high pressure without harming the surface area. It is used to clean calcium deposits from pool tiles or any type of various other surface areas, remove embedded fungi, as well as brighten cement color.

In eliminating paint for vehicle body job, bead blasting is chosen over sand blasting, as sand blowing up has a tendency to create a higher surface area account than bead blasting. Bead blasting is often used in creating a consistent surface area finish on machined parts. It is furthermore used in cleansing mineral samplings, the majority of which have a Mohs solidity of 7 or less as well as would certainly thus be harmed by sand.

9 Simple Techniques For Sand Blasting Sand

The very first blast wheel was patented by Wheelabrator in 1932. Hydro blowing up is not a kind of rough blowing up as no abrasive media sand for sand blaster is used. Hydro-blasting, commonly recognized as water blasting, is commonly made use of because it normally needs just one operator.This approach is suitable for cleaning interior and also exterior surfaces due to the fact that the driver is usually able to send out the stream of water right into locations that are tough to reach utilizing various other methods. Another benefit of hydro-blasting is the capability to recapture and also reuse the water, reducing waste as well as mitigating environmental effect.

The most common micro-abrasive blasting systems are commercial bench-mounted systems being composed of a power supply and mixer, exhaust hood, nozzle, and gas supply. Either the nozzle or component can be relocated in automated procedure.

The Definitive Guide for Sandblasting Near Me

Automated blowing up is often just an action in a bigger automated procedure, typically involving other surface area treatments such as prep work and coating applications.The air compressor gives a big quantity of high pressure air to a single or multiple "blast pots". Blast pots are pressurized, tank-like containers, loaded with unpleasant material, used to allow a flexible quantity of blowing up grit into the main blowing up line. The variety of blast pots is dictated by the quantity of air the compressor can supply.

Others are receptacle-fed types making them lightweight as well as extra mobile. In damp blowing up, the abrasive is presented into a pressurized stream of water or various other fluid, producing a slurry. Wet blowing official website up is typically made use of in applications where the marginal dust generation is wanted. Mobile applications may or may not reuse the unpleasant.

The smart Trick of Mobile Sandblasting Near Me That Nobody is Discussing

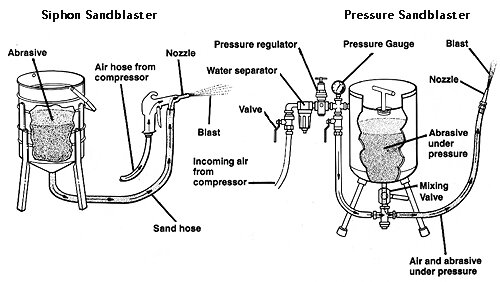

There are three systems typically utilized in a blast cupboard. 2, siphon and also pressure, are completely dry as well as one is wet: A siphon blast system (suction blast system) makes use of the pressed air to develop vacuum in a chamber (called the blast weapon). The adverse pressure draws abrasive right into the blast gun where the pressed air directs the abrasive via a blast nozzle.

Silicon carbide as well as boron carbide nozzles are much more use immune and also are commonly used with more difficult abrasives such as aluminium oxide. Inexpensive abrasive blowing up systems and smaller cupboards utilize ceramic nozzles.

The Basic Principles Of Abrasive Blasting

The vessel is pressurized to the very same pressure as the blast pipe connected to the bottom of the stress vessel. The rough is metered into the blast hose and also conveyed by the compressed gas through the blast nozzle. Wet blast closets utilize a system that infuses the abrasive/liquid click this slurry into a pressed gas stream.Report this wiki page